Senegal Solar Irrigation: Project Launch

Activities are in full swing for the solar irrigation project in Senegal (see Powering Agriculture: An Energy Grand Challenge for Development Initiative).

In February, Brett Gleitsmann, returned to the project site to meet with the community to officially introduce the project and begin to select the beneficiary producers. Our field technician, Mahécor Diouf, also carried out pump tests to establish a baseline for the gasoline-powered pumps that producers currently use. February is the middle of the Harmattan dry season which in that part of Senegal means cooler temperatures and plenty of dust. It was also the time for harvesting the first carrots of the year and for getting the onions out of their nurseries and into the fields for the coming season.

The project was warmly welcomed by the village chief, El Hadji Mbaye Diop, on behalf of the entire community of Gabar. The community is eager to collaborate over the coming year to put in place a successful solar irrigation system that will reduce their energy costs and allow them to make larger profits from their irrigated agriculture. During the meeting, we discussed the most critical points of how we can move forward and here is a brief outline of that discussion:

- Project scope: this installation in Gabar is one of three pilots in the MV project zone that will take place in 2014/2015. We chose Gabar due to its groundwater accessibility and high population density. Should the project be successful it will expand to reach other neighboring communities. The PV array of 8kW will be installed in a central location to provide power for pumping to a maximum of 10-12 producers. Power will only be available when the sun is shining as the systems will not have batteries. And so beneficiaries are encouraged to keep their existing gasoline pumps and to use them as a backup power source. All electricity will be sold on a pre-paid basis at a fixed tariff that will be transparent to all.

- Site for PV array: a technically-sound, centrally-located site for the 8kW solar array was chosen in collaboration with the community.

- Ownership: a contract will be put in place with input and signatories from the community, the project and the local government, to ensure that the infrastructure (PV panels, wiring, etc.) will belong to the local government (CR Léona). This will help to ensure equitable use of the infrastructure after the project involvement disappears in 2015.

- Eligibility: initially, only producers who have gasoline pumps and who are located within 300 meters of the PV array will be eligible to participate (see farms highlighted in orange in the map below). If the number of potential beneficiaries exceeds 10 then we will prioritize those who have drip systems and then we will prioritize those that are closest to the PV array.

- Cost sharing: the community is ready to provide the labor for digging trenches for wiring and for installing the solar array. It was also agreed that the beneficiary farmers would be required to pay a small fee to participate. The amount of the fee will be finalized once the infrastructure is in place but an amount of 10,000 CFA (20 USD) was discussed.

- Security: this is recognized as an important issue and the community will be responsible for protecting the infrastructure.

- Revenue: revenue from electricity sales will enter a jointly held bank account with multiple signatories and funds can be used to pay for maintenance, security and other approved activities. Details will be ironed out in the coming months.

Pump Tests

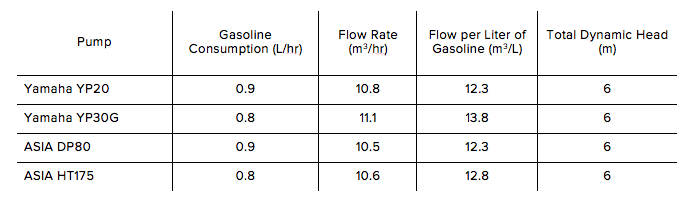

Our field technician, Mahécor Diouf, conducted a series of pump tests on four existing gasoline-powered pumps in the project zone (see results below). The pumps were tested for one-hour intervals to determine consumption rates and efficiency. We found that the pumps are producing roughly 13m3 of irrigation water per liter of gasoline at a total dynamic head of approximately 6 meters.

How efficient is this? In theory, it should take 0.21 kWh of energy to move this much water against that head. In this particular case it required 1 liter of gasoline, which has an energy content of 8.9 kWh. This means that overall the current system is roughly 2.4% efficient.

How does that compare to a typical gasoline-powered pumping system? Most of the inefficiencies are unavoidable and linked to the inherent inefficiency of thermal engines and impeller limitations, but there is room for improvement. Under ideal conditions, we may find that an optimized system has an overall efficiency of near 13%. This assumes gasoline engine efficiencies on the order of 25%, pump efficiencies on the order of 60%, and friction and minor system losses would consume at least 15% of the remaining energy. And so with one liter of gasoline (raw energy content = 8.9 kWh), we can assume that the maximum energy available at the end of the pipe would be 1.1 kWh. This means that there is room for improvement and we could potentially recover up to 0.9 kWh per liter of gasoline by improving pump efficiency and reducing losses. The impact of those improvements may be further constrained by physical realities such as impeller damage from turbid water and high operating temperatures.